HURST BOILER & WELDING CO.

For over 50 years, Hurst Boiler & Welding Co, Inc. has been a major supplier of gas, oil, wood and coal fired boilers to thousands of satisfied customers. Hurst manufactures a complete line of packaged firetube, firebox, vertical tubeless, and heat recovery boilers. Hurst’s current manufacturing facility has grown over the years to 314,000 square feet and they maintain over 350 employees at full production capacity. Through hard work, vision and daily hands on management style, Mr. Gene Hurst has built this company into the country’s premier industrial boilermaker.

Hurst has the engineering knowledge, the latest equipment and professional craftsmanship required to build boiler room systems that we are proud to represent.

Hurst Cyclone 4 Pass Vertical Tubeless Boiler:

- Capacities 6 to 100 HP

- 15# to 300# steam, 30# to 160# hot water

- Designed to handle swing and spike loads – quick recovery – quick response

Firebox: Series 45 and 100:

- Three pass firebox design

- Capacities 13.4 to 813 HP

- 15# Steam, 30 to 100# hot water

- Low Heat Release

- Large furnace volume for ultimate combustion efficiency

LPE and LPW Series “Through the Door” Design:

- Modified three pass Scotch Marine design

- Capacities 20 to 125 HP

- 15# steam, 30# hot water

- Heaviest designed boiler in its class

- Maximum width is 34 ½”

Dryback Scotch Marine: Series 200 and 300:

- Series 200: Two pass dryback

- Series 300: Three pass dryback

- Capacities 15 to 800 HP

- 15# to 300# steam, 30# to 160# hot water

- 5 Sq. Ft. heating surface per BHP

- Large combustion chamber with low heat release for complete combustion

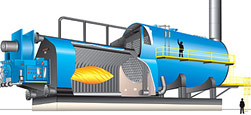

Wetback Scotch Marine: Series 400 and 500:

- Series 400: Three pass wetback

- Series 500: Four pass wetback

- Capacities 30 to 2000 HP

- 15# to 300# steam, 30# to 160# hot water

- 5 Sq. Ft. heating surface per BHP

- Large combustion chamber with low heat release for complete combustion

Ohio Specials: Series 400:

- Three pass wetback

- Capacities 100 to 225 HP

- 15# to 300# steam

- 358 Sq. Ft. heating surface

- Eliminates requirement for licensed operator in Ohio

- Large combustion chamber with low heat release for complete combustion

Boiler Room Accessories:

- Packaged boiler feed systems – Feedmiser

- Packaged deaerator systems – Oxy-Miser – .005 ccs/liter

- Blowdown separator systems

Solid Fuel Fired: Multi-Fuel Hybrid Series:

- Fully engineered and packaged steam and hot water boilers

- Sawdust, bark, hog fuel, paper, hulls, rubber, coal and sludge

- Gasifiers

Stackmaster:

- Internal stack economizer

- Increase efficiency of boiler, lower operating costs

- Complete pre-piped package direct from factory

- Ideal for “Ohio Special” boilers.